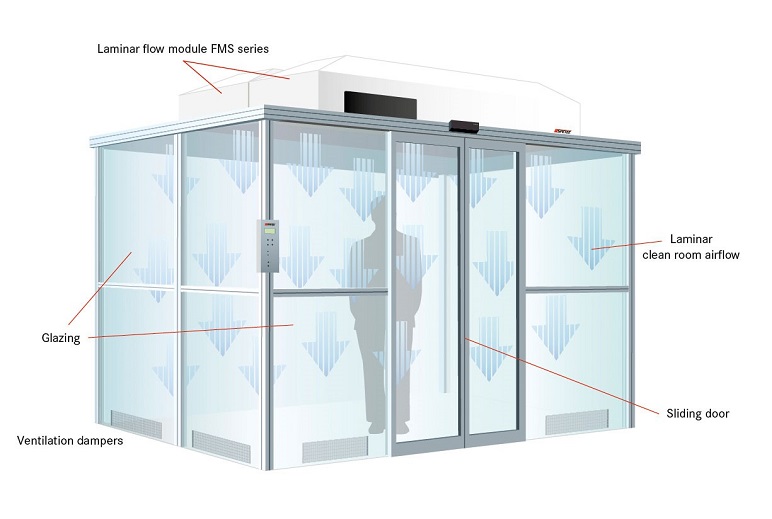

Clean room cells with hard wall panels are mainly used in areas that demand an extremely high level of process reliability. Overpressure prevents particels from entering the clean room. The flexible wall system makes it possbile to extend the clean room cell at any time.

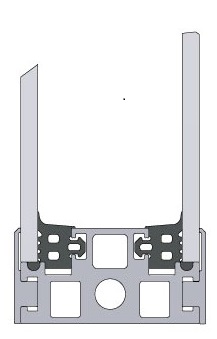

Wall elements:

Flush-mounted

For applications corresponding to ISO classes 5 and 6 and GMP A through D

we recommend our flush-mounted system:

Double-glazing or wall filling elements are flush-mounted:

The Benefit: This ensures that deposits of dust do not build up and facilitates cleaning and disinfection.

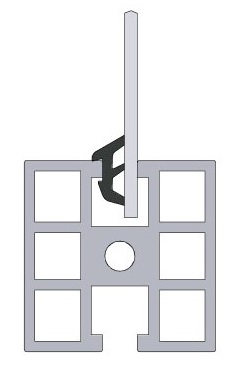

Standard

The standard wall element is intended for clean rooms of ISO classes 7 and 8.

The standard wall element is intended for clean rooms of ISO classes 7 and 8.

The panes of glass or the wall filling elements are installed centrally in the groove of the metal section.

The Benefit: The cell can be offer more cost-effective because of less use of materials.

Optional features for hard wall systems:

- Aluminium or steel section support frame (dimensions to order)

- Airlock for materials and personnel

- Double doors with mutual locking system

- Side elements made from acrylic or laminated glass or aluminium composite panel

- Transparent or tinted window elements

- Electrical sliding door with air lock function

High performance filter:

The Spetec laminar flow box FMS uses a type H 14 filter. It features a retention rate of 99.995%. This means that at a particle size of 0.12 μm (according to MPPS), the filter removes at least 99.995% of all particles. At a particle size of 0.3 μm, the retention rate is approx. 99.9995%.

By using the H 14 filter, the Spetec laminar flow module has an isolation factor of 10. This means that the air quality inside the laminar flow is improved by a factor of at least 10 000 relative to the ambient air.

Application example:

With the use of a SPETEC® clean room cell the particle concentration is reduced from approximately 15 Mio/m3 (size 0.12 μm, MPPS) to about 1,500 particles within the cell. This corresponds with a room class of DIN ISO 5.

Control panel

The flow velocity can be controlled in 8 steps. The controls include the “night reduction” (eco) mode to save energy costs, and the “MAX” function to clean the workstation, parts, or equipment if applicable.

- 8 level adjustment of the flow velocity with night reduction and flushing function

- LCD display with selected flow velocity in m/second

- Service and interval indicator, dependent on the usage period

- LED fault indicator

- Connection options for building control systems (remote monitoring)

- Interior light switch on the control panel

- Automatic flow adjustment with filter replacement indicator

Through the use of latest generation EC fans with a very high efficiency, the power draw is reduced to a minimum.

Examples of SPETEC cleanrooms